Purpose

The RT7285C is a synchronous step-down converter with Advanced Constant On-Time (ACOT™) mode control. It can deliver up to 1.5A output current from a wide input voltage range of 4.3V to 18V.This document explains the function and use of the RT7285C evaluation board (EVB) and provides information to enable operation and modification of the evaluation board and circuit to suit individual requirements.

Introduction

General Product Information

The RT7285C is a synchronous step-down converter with Advanced Constant On-Time (ACOT™) mode control. The ACOT™provides a very fast transient response with few external components. The low impedance internal MOSFET supports high efficiency operation with wide input voltage range from 4.3V to 18V. The proprietary circuit of the RT7285C enables to support all ceramic capacitors. The output voltage can be adjusted between 0.6V and 8V. The RT7285C also provides output under voltage protection and thermal shutdown protection. The low current (<4μA) shutdown mode provides output disconnection, enabling easy power management in battery-powered systems. The RT7285C is available in TSOT-23-6 package.

Product Feature

- ±1.5% High Accuracy Feedback Voltage

- 4.3V to 18V Input Voltage Range

- 1.5A Output Current

- Integrated N-MOSFET Switches

- ACOTTM mode control

- Fixed Frequency Operation : 500kHz

- Output Adjustable from 0.6V to 8V

- Up to 95% Efficiency

- Fast Transient Response

- Stable with Low-ESR Ceramic Output Capacitors

- Cycle-by-Cycle Over Current Protection

- Input Under Voltage Lockout

- Output Under Voltage Protection

- Thermal Shutdown Protection

- RoHS Compliant and Halogen Free

Key Performance Summary Table

|

Key Features

|

Evaluation Board Number: PCB007_V1

|

|

Default Input Voltage

|

12V

|

|

Max Output Current

|

1.5A

|

|

Default Output Voltage

|

1.2V

|

|

Default Marking & Package Type

|

RT7285CGJ6, TSOT-23-6

|

|

Operation Frequency

|

Steady 500kHz at all loads

|

|

Other Key Features

|

ACOTTM for Fast Transient Response

|

|

Protection

|

Output Under-Voltage Protection (hiccup mode):

Cycle-by-cycle Current Limit

Thermal Shutdown

|

Bench Test Setup Conditions

Headers Description and Placement

Please carefully inspect the EVB IC and external components, comparing them to the following Bill of Materials, to ensure that all components are installed and undamaged. If any components are missing or damaged during transportation, please contact the distributor or send e-mail to evb_service@richtek.com

Test Points

The EVB is provided with the test points and pin names listed in the table below.

|

Test point/

Pin name

|

Signal

|

Comment (expected waveforms or voltage levels on test points)

|

|

VIN

|

Input voltage

|

Input voltage range= 4.3V to 18V

|

|

VOUT

|

Output voltage

|

Default output voltage = 1.2V

Output voltage range= 0.6V to 8V

(see ‘’ Output Voltage Setting’’ section for changing output voltage level)

|

|

SW

|

Switching node test point

|

SW waveform

|

|

EN

|

Enable test point

|

Enable signal. Drive EN or install a shorting block on Jumper JP2 to enable operation or disable operation.

|

|

JP2

|

Chip enable control

|

Install jumper or drive EN directly to enable or disable operation

|

|

BOOT

|

Boot strap supply test point

|

Floating supply voltage for the high-side N-MOSFET switch

|

|

GND

|

Ground

|

Ground

|

Power-up & Measurement Procedure

1.Apply a 12V nominal input power supply (4.3V < VIN < 18V) to the VIN and GND terminals.

2.The EN voltage is pulled to logic high by R5 (100kΩ to VIN) to enable operation. Drive EN high (>1.5V) to enable operation or low (<0.4V) to disable operation.

3.Verify the output voltage (approximately 1.2V) between VOUT and GND.

4.Connect an external load up to 1.5A to the VOUT and GND terminals and verify the output voltage and current.

Output Voltage Setting

Set the output voltage with the resistive divider (R2, R3) between VOUT and GND with the midpoint connected to FB. The output is set by the following formula:

The installed VOUT capacitors (C9, C10) are 22μF, 16V X5R ceramic types. Do not exceed their operating voltage range and consider their voltage coefficient (capacitance vs. bias voltage) and ensure that the capacitance is sufficient to maintain stability and provide sufficient transient response for your application. This can be verified by checking the output transient response as described in the RT7285C IC datasheet.

Schematic, Bill of Materials & Board Layout

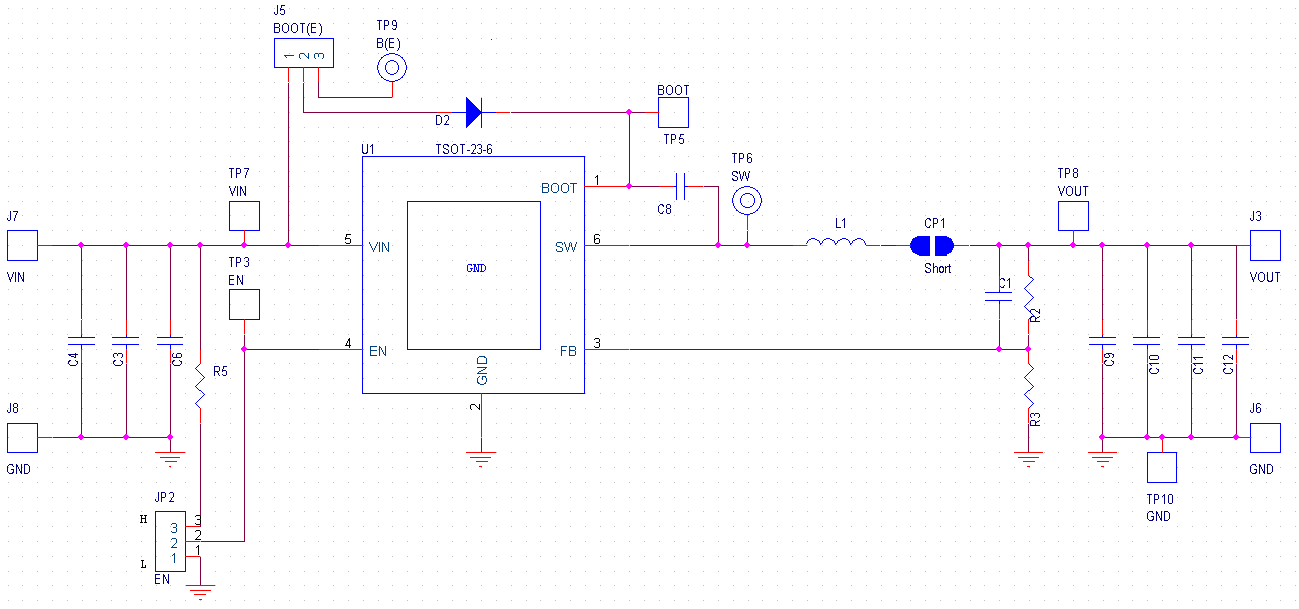

EVB Schematic Diagram

C3, C4: 10μF/50V/X5R, 1206, TDK C3216X5R1H106K

C9, C10: 22μF/16V/X5R, 1210, Murata GRM32ER61C226K

L1: 2μH TAIYO YUDEN NR8040T2R0N, DCR=9mΩ

Bill of Materials

|

Reference

|

Qty

|

Part number

|

Description

|

Package

|

Manufacture

|

|

U1

|

1

|

RT7285CGJ6

|

DC-DC Converter

|

TSOT-23-6 (FC)

|

RICHTEK

|

|

C3, C4

|

2

|

C3216X5R1H106K160AB

|

10μF/±10%/50V/X5R

Ceramic Capacitor

|

1206

|

TDK

|

|

C9, C10

|

2

|

GRM32ER61C226KE20#

|

22μF/±10%/16V/X5R

Ceramic Capacitor

|

1210

|

Murata

|

|

C6, C8, C12

|

3

|

C1608X7R1H104K080AA

|

0.1μF/±10%/50V/X7R

Ceramic Capacitor

|

0603

|

TDK

|

|

C1, C11, D2

|

0

|

|

Not Installed

|

0603

|

|

|

L1

|

1

|

NR8040T2R0N

|

2.0μH/7.4A/±30%, DCR=9mΩ, Inductor

|

8mmx8mmx4mm

|

TAIYO YUDEN

|

|

R2

|

1

|

|

10kΩ/±1%, Resistor

|

0603

|

|

|

R3

|

1

|

|

10kΩ/±1%, Resistor

|

0603

|

|

|

R5

|

1

|

|

100kΩ/±1%, Resistor

|

0603

|

|

|

CP1

|

1

|

|

Short

|

|

|

|

JP2, J5

|

2

|

|

3-Pin Header

|

|

|

|

GP

|

4

|

EN, B( E), BOOT, SW

|

Golden Pin

|

|

|

|

TP

|

3

|

Vout, GND, VIN

|

Test Pin

|

|

|

|

J3, J6, J7, J8

|

4

|

VIN, VOUT, GND, GND

|

Test Pin

|

|

|

EVB Layout

Top View (1stlayer)

Bottom View (4th Layer)

Component Placement Guide—Component Side (1stlayer)

PCB Layout—Component Side (1stLayer)

PCB Layout—Bottom Side (4th layer)